stainless steel is used to describe a family of about 200 alloys of steel with remarkable heat and corrosion resistance properties. The carbon percentage can range from 0.03% to 1.2%.

Its distinguishing characteristic is the high amount of chromium. Stainless steel contains a minimum of 10.5% of chromium that improves its corrosion resistance and strength.

Stainless steel including Austenitic, Martensitic, Ferritic and Duplex. In difference countries and under different standards, people easy to get in confusion with material types. For example, some people think A2 and 18-8 stainless steel and SS304 is the same material. In real story, we should use assume instead of think here. A2 and 18-8 including many types, A abbreviation from Austenitic, 2 is the grade.ASTM introduce 18-8 in 1924 meeting original from material 20-7 which invented by Benno Strauss and Eduard Maurer. Number 18/8 indicates that the steel is composed of 18% chromium and 8% nickel, making it highly resistant to corrosion and oxidation. SS304 is one of typical A2 stainless steel and 18-8 stainless steel.

Base on ISO3506-1, stainless steel fasteners material includes 4 groups and 14 grades[with chart behind]. Austenitic list 6 grade as A1 A2 A3 A4 A5 and A8, Martensitic list 3 grade C1 C3 C4,Ferritic F1 and Duplex 4 grade D2 D4 D6 D8. Commonly using material A1 named SS303,A2 named SS304,A3 named SS321,A4 named SS316,A5 named SS316Ti. C1 called 410,C3 called 431,C4 called 416.F1 is 430.D2 named 2304,D4 named 2202,D6 named 2205,D8 named 2507.

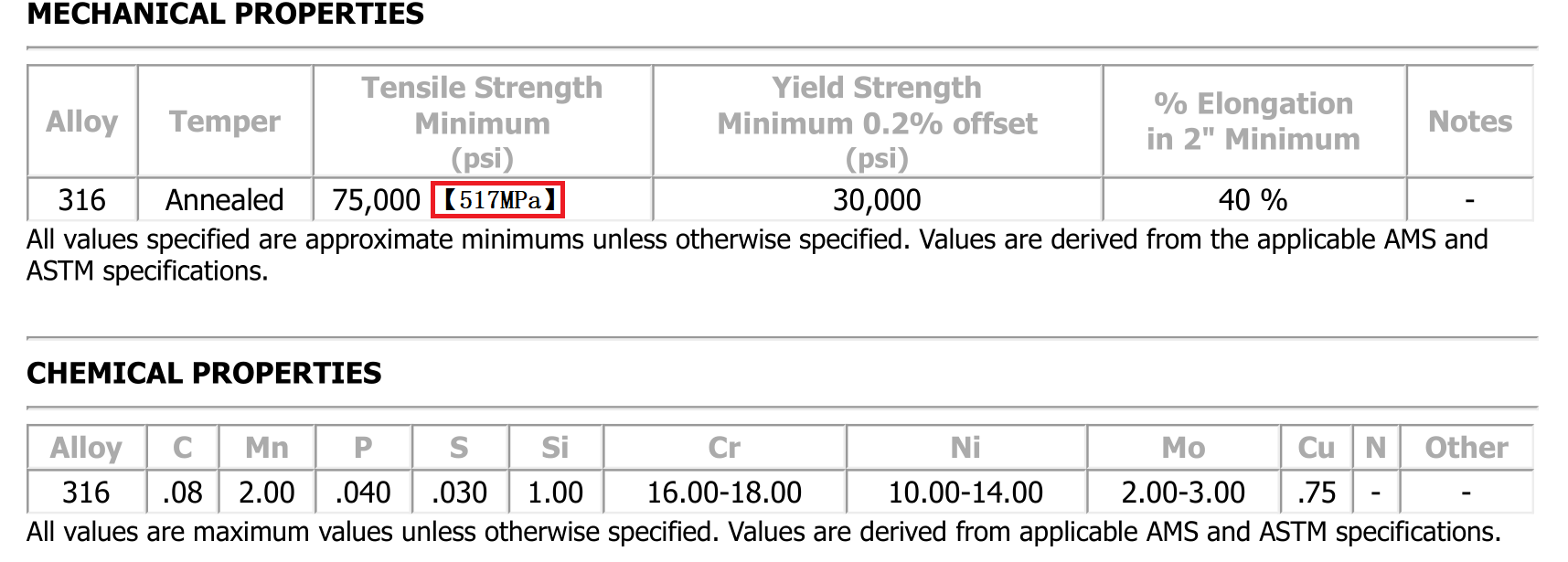

Typical stainless steel name A4-80 is a good example to introduce material and physical performance, A4 match with material SS316 or 316L,-80 means tensile strength 800MPa.However SS316 spec data UTS515~655MPa,How to achieve 800MPa Min?First solution is cold-pull raw wire to 800MPa min and then cold forming or machining to final part. Second way is hot forging since cold pull diameter size limited by the huge cold-pull equipment. In hot forging, accurate temperature control to avoid anneal to guarantee the tensile strength 800MPa Min is critical and difficult, limited suppliers have the ability to process it reliable with acceptable cost. (1MPa≈145psi)

In real using, people puzzled with stainless steel easy to get corrosion. After Eastec team investigation and studying the environment, acid or alkaline substance or Fe-base-dust is the root cause and stainless steel is anti-rust not never rust, keep the working space clean and suitable passivation is helpful to improve the corrosion resistance properties.

Customer service 1

Customer service 1  Customer service 2

Customer service 2