Silver Undercoat Selection Guide for Plating Applications

Time:2024-04-23 15:25:03 Source:未知 Click:次

Silver plating, as a surface treatment technology, is widely used in various industries such as electronics, electrical, instrumentation, precision instruments, and more. In different industries, there are different requirements for the selection of undercoat materials for silver plating. This article will introduce you to the guide for selecting undercoat materials for silver plating in different industries.

一、Electronics Industry

In the electronics industry, silver plating is primarily used in the manufacturing of printed circuit boards (PCBs). In the PCB manufacturing process, the choice of undercoat material is crucial. Commonly used undercoat materials include copper, aluminum, FR-4, among others. Copper is widely used due to its good conductivity and machinability; aluminum is favored for its lightweight and high thermal conductivity, which is suitable for applications requiring better heat dissipation; FR-4 is a performance- excellent epoxy glass fiber cloth substrate with high mechanical strength and heat resistance.

二、Electrical Industry

In the electrical industry, silver plating is mainly used for the conductors and insulators of wires and cables. For conductors, commonly used materials include copper, aluminum, magnesium, etc.; for insulators, materials such as polyvinyl chloride (PVC), polyethylene (PE), polytetrafluoroethylene (PTFE), and others are frequently used. The selection of these materials depends on the environment in which the wires and cables will be used, as well as the voltage level requirements.

三、Instrumentation Industry

In the instrumentation industry, silver plating is applied to parts such as connectors and terminal blocks on instruments. For these applications, common undercoat materials include copper, aluminum, stainless steel, and others. Copper is preferred for its good conductivity and machinability; aluminum is chosen for its lightweight and high thermal conductivity, which is suitable for applications requiring better heat dissipation; stainless steel is chosen for its corrosion resistance and wear resistance in harsh environments.

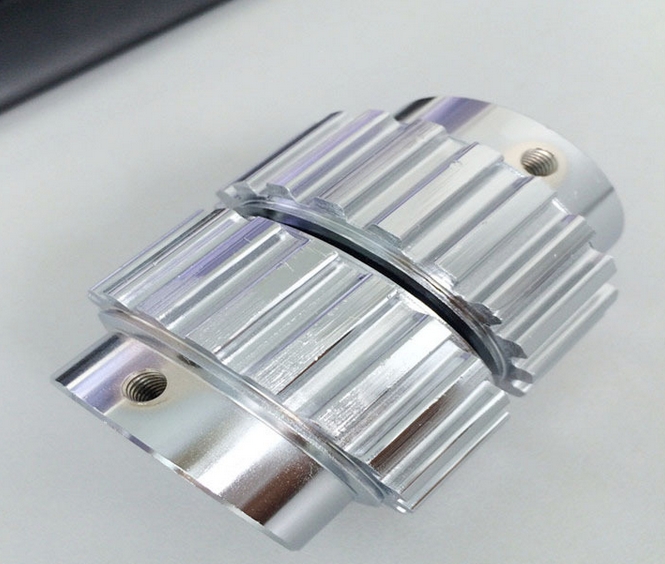

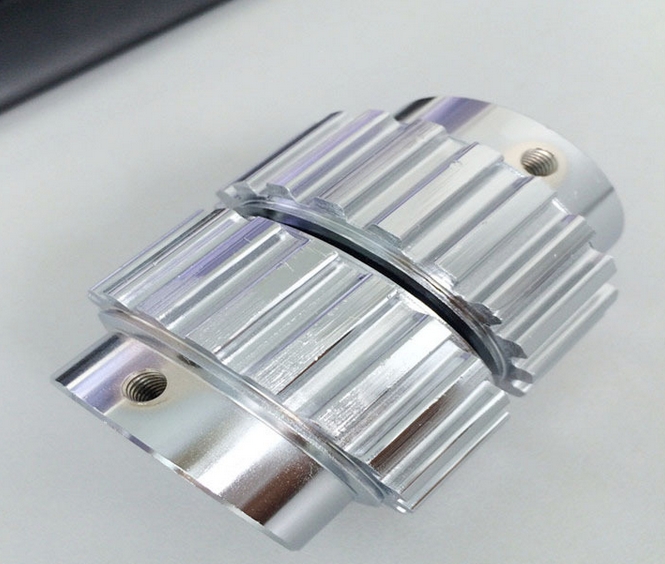

四、Precision Instrument Industry

In the precision instrument industry, silver plating is primarily used to improve the conductivity, thermal conductivity, and aesthetics of instruments. Common undercoat materials include copper, aluminum, stainless steel, and others. The selection of these materials depends on the environmental conditions and performance requirements of the precision instruments.

In summary, when selecting undercoat materials for silver plating, it is essential to consider the specific application scenarios and performance requirements of different industries. Additionally, the choice of plating process is also very important, ensuring that the quality of the plating layer, adhesion, corrosion resistance, and other indicators meet industry standards. In the actual production process, it is also necessary to pay attention to environmental protection and cost factors to achieve sustainable development.

It is hoped that this article can provide you with a useful reference for the selection of undercoat materials for silver plating. For further technical details and assistance, please feel free to contact us. We will be happy to provide you with professional solutions and quality services.

Customer service 1

Customer service 1  Customer service 2

Customer service 2