Precision: Centerless Grinder vs Cylindrical Grinder

Time:2024-01-18 17:51:04 Source:未知 Click:次

In the machinery manufacturing industry, grinding is a commonly used precision processing method that can effectively improve the dimensional accuracy and surface quality of workpieces. Among them, centerless grinding machine and external cylindrical grinding machine are two common grinding equipment. However, many companies often feel confused when facing the choice, not knowing which equipment to choose. This article will compare the machining accuracy of centerless grinding machine and external cylindrical grinding machine, as well as their precision requirements and application ranges.

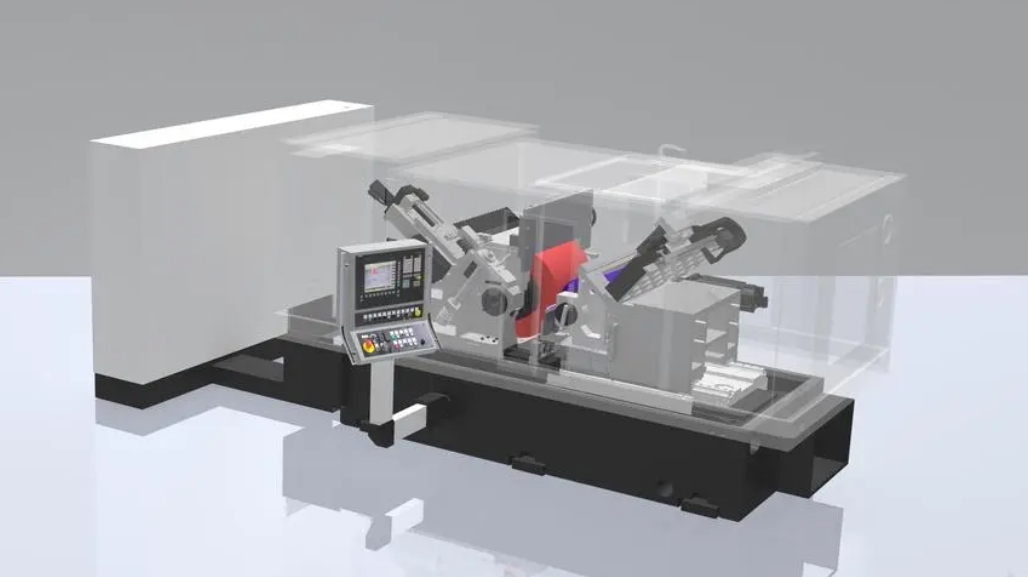

Firstly, let's look at the machining accuracy of the centerless grinding machine. The centerless grinding machine is a device that uses centerless grinding method, mainly used for precision grinding of the external surfaces of cylinders, cones or other shapes formed by straight lines. Its advantage is high processing accuracy and efficiency, suitable for mass production. According to actual production experience, the processing accuracy of the centerless grinding machine can generally reach IT5-IT6 level or even higher. Therefore, if the company's part accuracy requirements are high or it needs to produce the same parts in large quantities, then the centerless grinding machine will be a better choice.

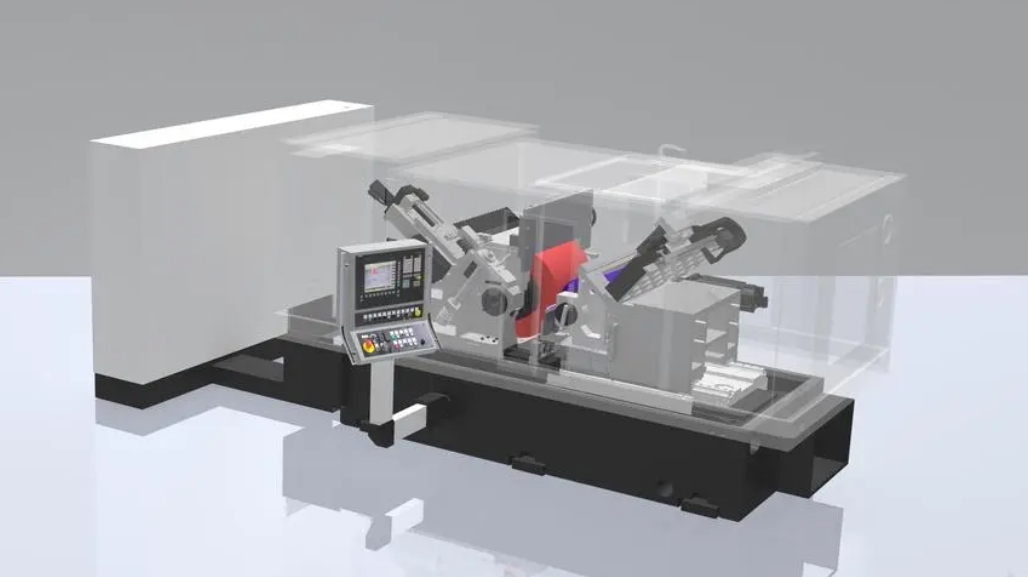

Next, let's look at the machining accuracy of the external cylindrical grinding machine. The external cylindrical grinding machine is mainly used for precision grinding or finishing of the external surfaces of cylinders, cones or other shapes formed by straight lines. Its advantage is that it can grind inner holes, end faces and various curved surfaces, suitable for single piece and small batch production. According to actual production experience, the processing accuracy of the external cylindrical grinding machine can generally reach IT6-IT7 level or even higher. Therefore, if the company's part accuracy requirements are extremely high or it needs to frequently change parts types, then the external cylindrical grinding machine will be more suitable.

In terms of application scope, the centerless grinding machine is mainly used for mass production of high-precision parts such as bearings, gears, piston rings, valves, and valve plates. On the other hand, the external cylindrical grinding machine is widely used in single piece and small batch production of automotive, motorcycle, bearing, tool, textile machinery, agricultural machinery and other industries.

In general, both centerless grinding machine and external cylindrical grinding machine have their own advantages. The choice of which equipment to use mainly depends on the actual needs of the company. When choosing, the company should comprehensively consider its own production scale, part accuracy requirements and equipment investment cost and other factors to ensure that the most suitable equipment is purchased. At the same time, the company should regularly maintain and repair the equipment to ensure the normal operation of the equipment and processing quality.

Finally, although the machining accuracy of both centerless grinding machine and external cylindrical grinding machine is very high, they cannot replace other types of grinding equipment such as surface grinding machine and internal cylindrical grinding machine. Therefore, when purchasing equipment, companies also need to consider their own production needs and select appropriate grinding equipment accordingly.