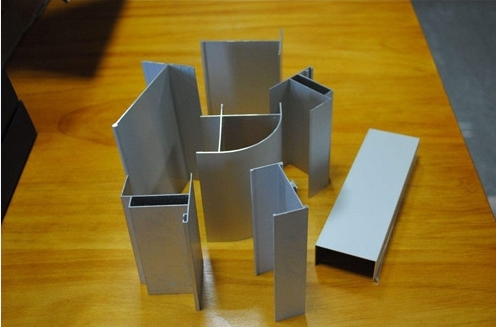

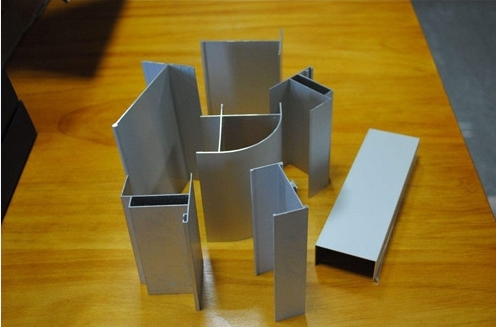

Aluminum Oxidation Treatment Process

Time:2023-12-15 13:38:23 Source:未知 Click:次

In the manufacturing industry, aluminum oxidation treatment is a common surface treatment process. It can not only improve the corrosion resistance, wear resistance, and insulation of aluminum parts, but also enhance their appearance, making them more durable and attractive. So, what is the specific process flow of aluminum oxidation treatment? This article will detail the process flow of aluminum oxidation treatment.

Firstly, pretreatment is the first step of aluminum oxidation treatment. The main purpose of pretreatment is to remove impurities such as oil stains, scales, burrs, etc. on the surface of aluminum parts, creating good conditions for subsequent oxidation treatment. Pretreatment methods mainly include mechanical polishing, chemical cleaning, and sandblasting.

Next, anodizing is the core step of aluminum oxidation treatment. Anodizing is a process in which aluminum parts act as anode and undergo oxidation reaction in a certain electrolyte to form an aluminum oxide film. The conditions of anodizing include the composition of the electrolyte, temperature, voltage, current density, etc. and need to be controlled according to specific product requirements.

After anodizing, sealing is needed. The purpose of sealing is to fill the micropores of the aluminum oxide film, improve the compactness of the aluminum oxide film, and further improve the corrosion resistance and wear resistance of aluminum parts. Sealing methods mainly include hot water sealing, steam sealing, and high-temperature hot sealing.

Finally, it's time for product inspection and packaging. Inspection is to check whether the surface quality, color, thickness, etc. of the aluminum parts meet the requirements. Packaging is to protect qualified products with protective packaging to ensure that they are not damaged during transportation and storage.

The above is the basic process flow of aluminum oxidation treatment. It should be noted that different products and requirements may require different process flows and parameters. Therefore, when carrying out aluminum oxidation treatment, we need to select and adjust process flows and parameters flexibly according to specific situations.

In addition, although aluminum oxidation treatment has many advantages, there are also some problems, such as oxidation spots, color difference, etc. The emergence of these problems may affect the appearance and performance of products. Therefore, we need to continuously research and explore new processing methods and technologies to solve these problems.

In general, aluminum oxidation treatment is a very important surface treatment process. Only by mastering the correct process flow and methods can we ensure the effect and quality of aluminum oxidation treatment. We hope this introduction can be helpful to everyone. If you have any questions or need further information, please feel free to contact us at any time. We will be happy to serve you.